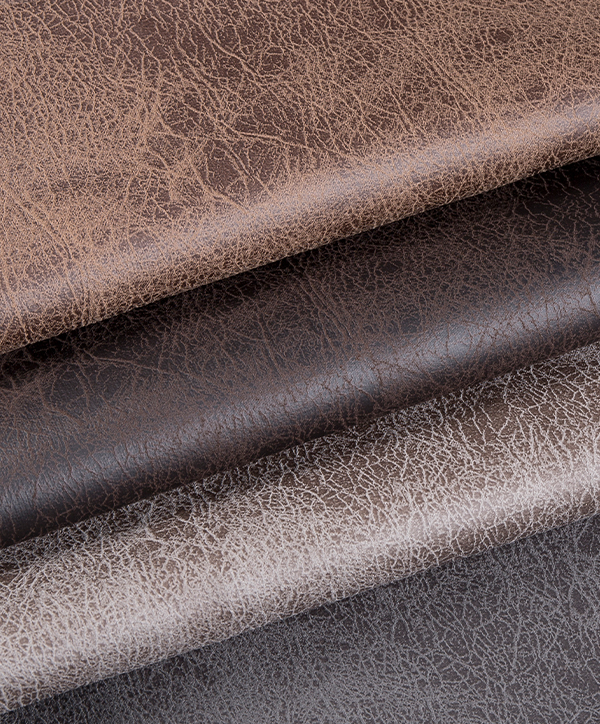

In the field of modern home decoration, sofas, as the core furniture of the living room, need to be not only comfortable and practical, but also need to show the owner's taste and style through appearance design. As a high-end decorative material, sofa hot stamping fabric (Sofa Hot Stamping Fabric) has become the first choice of many high-end sofa manufacturers with its unique visual effect and excellent texture.

Production process

The production process of sofa hot stamping fabric combines traditional textile technology with modern hot pressing technology, and mainly includes the following steps:

Base fabric selection

The base fabric is the basis of the hot stamping fabric, usually made of high-density polyester, cotton and linen blends or other durable fabrics. The choice of base fabric directly affects the feel, strength and applicability of the fabric.

Design and plate making

According to customer needs, designers will draw hot stamping patterns or textures and make them into metal templates. These templates determine the pattern details and three-dimensional effects of the final product.

Hot stamping

This is the core link of the entire process. The metal foil or coating is placed on the surface of the base fabric and pressed onto the fabric through high temperature and high pressure equipment. Precise control of temperature, pressure and time is the key to ensuring the hot stamping effect.

Finishing

After the hot stamping is completed, the fabric will be cleaned, shaped and functionally treated (such as waterproof, anti-fouling or wear-resistant treatment) to enhance its durability and practicality.

Advantages of hot stamping fabrics for sofas

The reason why hot stamping fabrics for sofas are favored by the market is mainly due to its significant advantages in the following aspects:

Luxury appearance

The hot stamping process gives the fabric a metallic luster and exquisite texture, making it look more noble and elegant, which is very suitable for the design of high-end sofas.

Diverse designs

Through different templates and hot stamping techniques, rich patterns and textures can be achieved, from simple geometric lines to complex floral patterns, to meet the aesthetic needs of different consumers.

Strong durability

Despite the metallic luster on the surface, the hot stamping fabric for sofas still maintains the basic properties of the fabric, such as softness and wear resistance, and is suitable for long-term use.

Easy to clean

The hot stamping fabrics that have been specially treated are usually anti-fouling and waterproof. Daily cleaning only requires a light wipe with a damp cloth, which greatly reduces maintenance costs.

Environmental protection potential

With the increasing awareness of environmental protection, many manufacturers have begun to adopt recyclable materials and non-toxic coatings to reduce the impact on the environment.

Application areas

Due to its unique properties, sofa bronzing fabrics have been widely used in many fields:

High-end home decoration

In luxury villas, hotel lobbies and high-end apartments, sofa bronzing fabrics are often used to make high-end sofas, seats and cushions, adding a sense of luxury to the space.

Commercial space

Shopping mall lounges, cafes, restaurants and other places also favor sofa bronzing fabrics because their durability and beauty can attract customers and enhance the overall atmosphere.

Automotive interior

In high-end car seats and interiors, sofa bronzing fabrics are widely used because of their lightweight and beautiful characteristics, adding a sense of technology and luxury to the interior space of the car.

Customized furniture

For consumers who pursue personalization, sofa bronzing fabrics can customize patterns and colors according to customer needs to create unique furniture works.

Environmental challenges and future prospects

Although sofa bronzing fabrics perform well in appearance and function, their production and disposal still face certain environmental challenges. For example, metal foils and coatings may contain non-degradable chemicals, and the recycling rate of waste fabrics is low. To this end, the industry is actively exploring more environmentally friendly solutions, such as developing degradable coatings or using bio-based materials to replace traditional raw materials.

Looking ahead, as consumers' demand for personalization and sustainable development continues to increase, sofa gilding fabrics are expected to be used in more areas. The introduction of intelligent technology may also bring more possibilities, such as embedding smart sensors to monitor the use status of sofas, or developing smart fabrics with self-repair functions.

With its luxurious appearance, diverse designs and excellent functionality, sofa gilding fabrics are gradually changing the landscape of the traditional home decoration industry. It not only brings consumers a higher quality of life experience, but also provides designers with more creative space. In the future, with the continuous breakthrough of technology, sofa gilding fabrics will surely play a greater role worldwide and become an important representative of high-end furniture and decorative materials.

ENGLISH

ENGLISH  Türk

Türk عربى

عربى русский

русский